Cable entries

The efficient solutions.

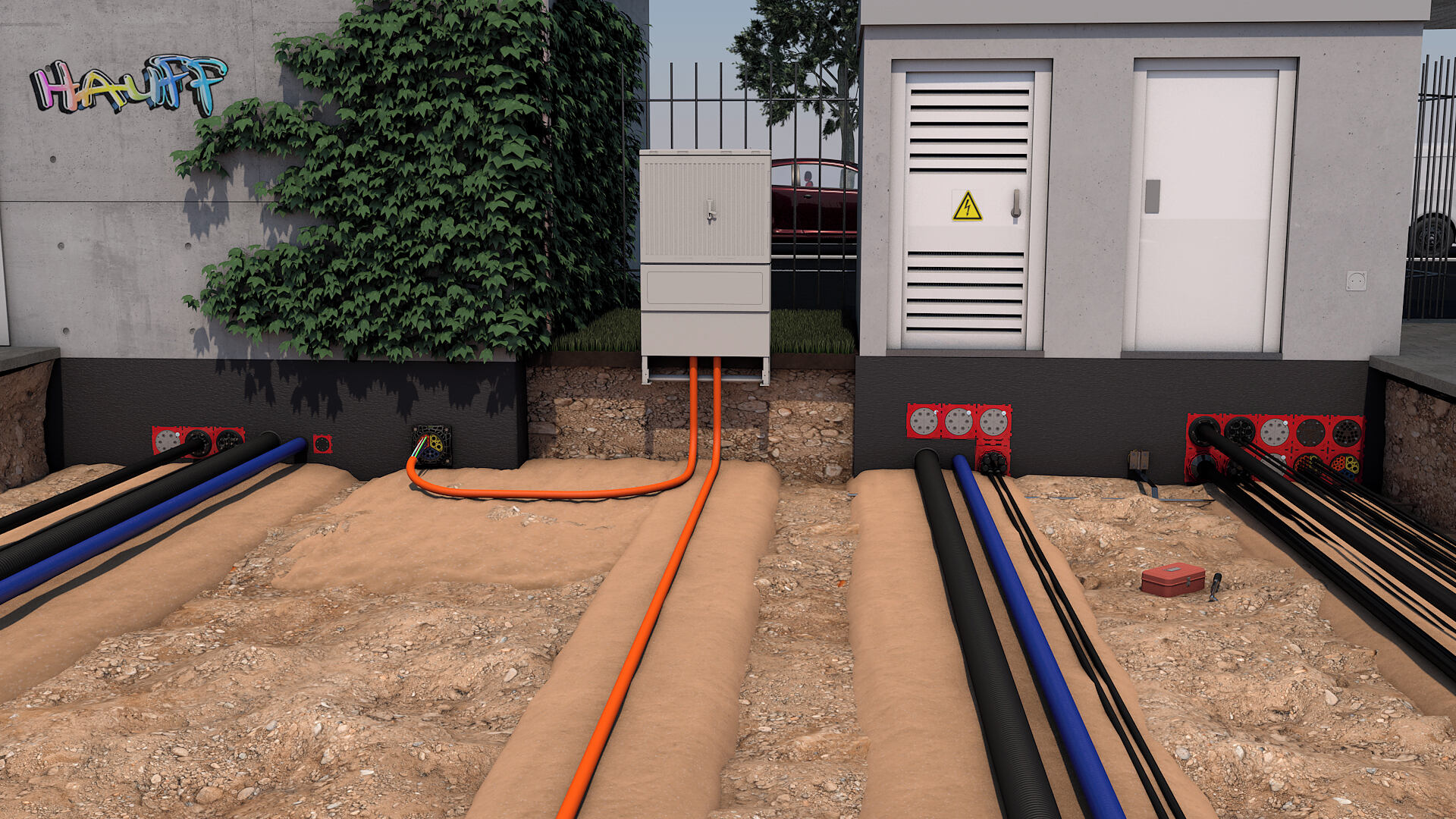

Hauff-Technik has been a manufacturer of cable entries since back in 1975. Its range, which has been continuously enhanced and expanded, offers the right solution for all requirements relating to the sealing and entry of cables. Our cable entries, which are manufactured to the highest possible quality standards, impress by delivering maximum flexibility in planning and execution. What's more, they are incredibly user-friendly and can be relied upon for effective sealing. We also offer suitable solutions for cable duct connections, whatever your requirements.

Whether the entry has already been taken into account during planning of the building or subsequent installation is required for an existing building: Hauff-Technik always has the right solution, whatever the application – electric cables, communication cables or earthing conductors – and whatever the installation scenario – through the floor slab, through the wall or as an entry on the roof – from inserts through to retrofit dowelling solutions and system inserts such as press seals or system covers.

General information

- REACH

- System overview HSI 150 and KES

- System overview HSI 90 and KES

- General product information press seals

- General product information cable sealing system

- General product information cable entry system

- General product information wall sleeves

- General product information press seals

- How do I measure correctly?

Professional Cable Entry Solutions by Hauff-Technik

A reliable cable entry is crucial for protecting buildings during utility installations, keeping harmful gases and moisture out. Hauff-Technik delivers advanced sealing solutions for a wide range of building entry points, ensuring comprehensive protection of your building's interior and structural foundation.

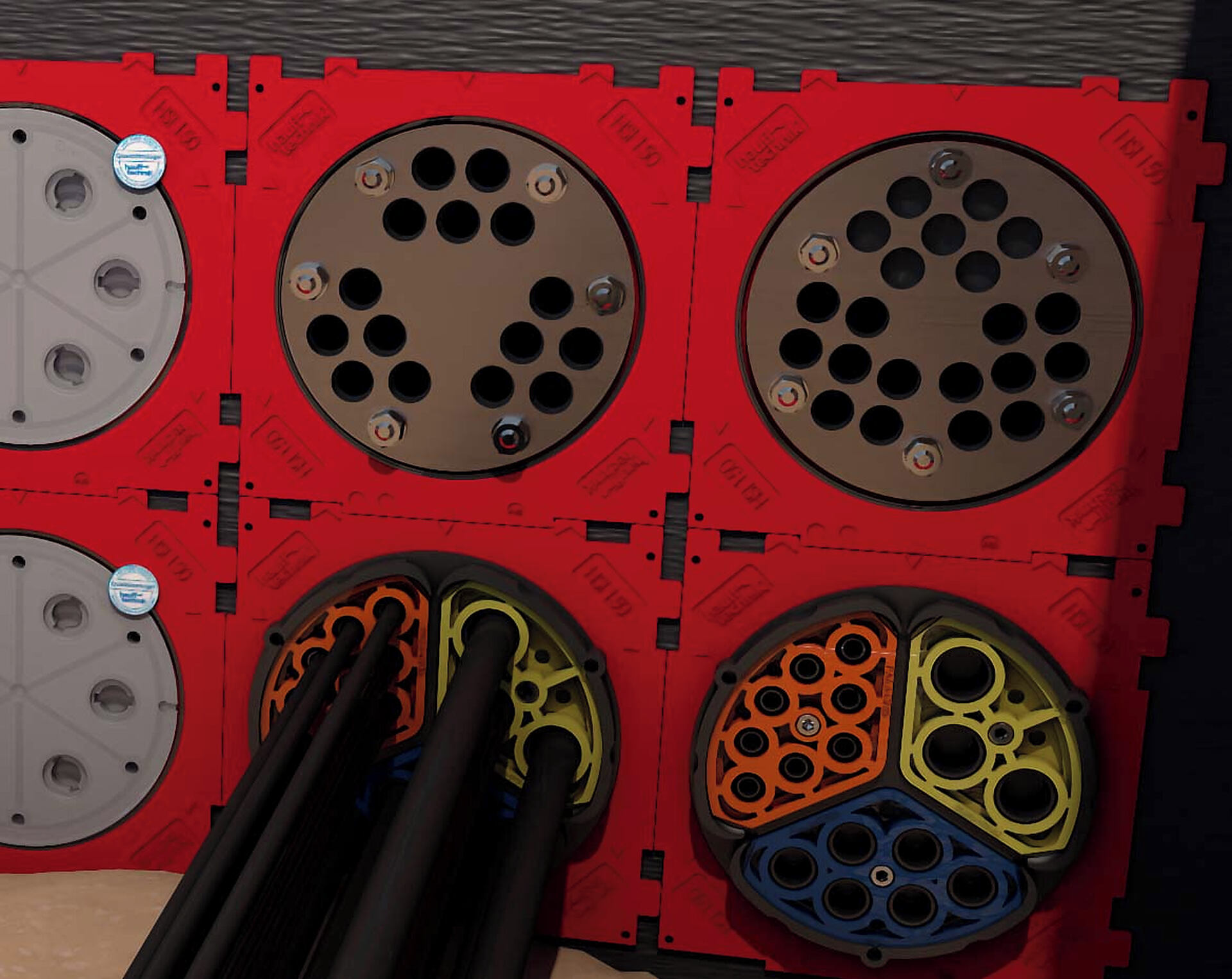

Cable Seals for All Types of Cable Entries

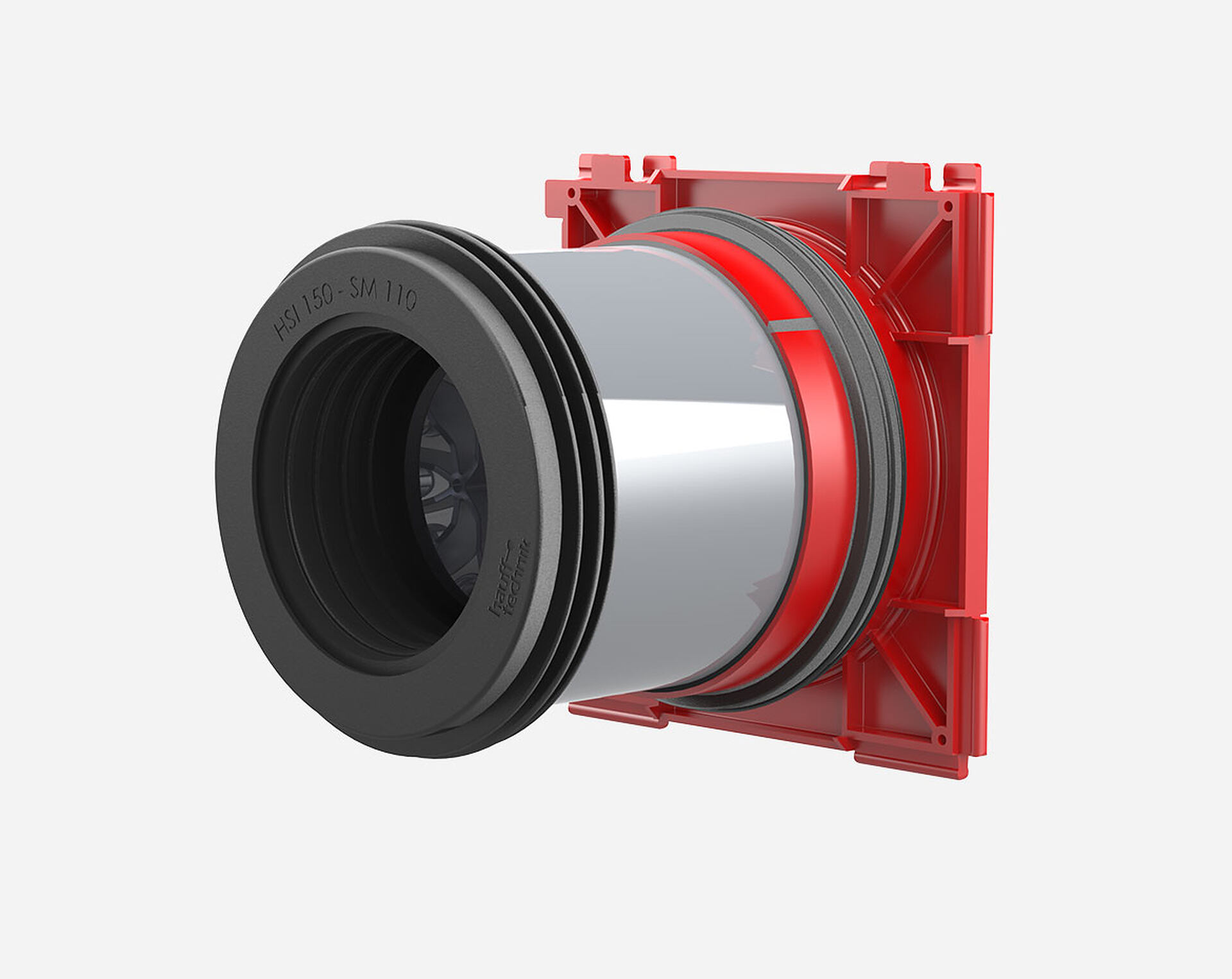

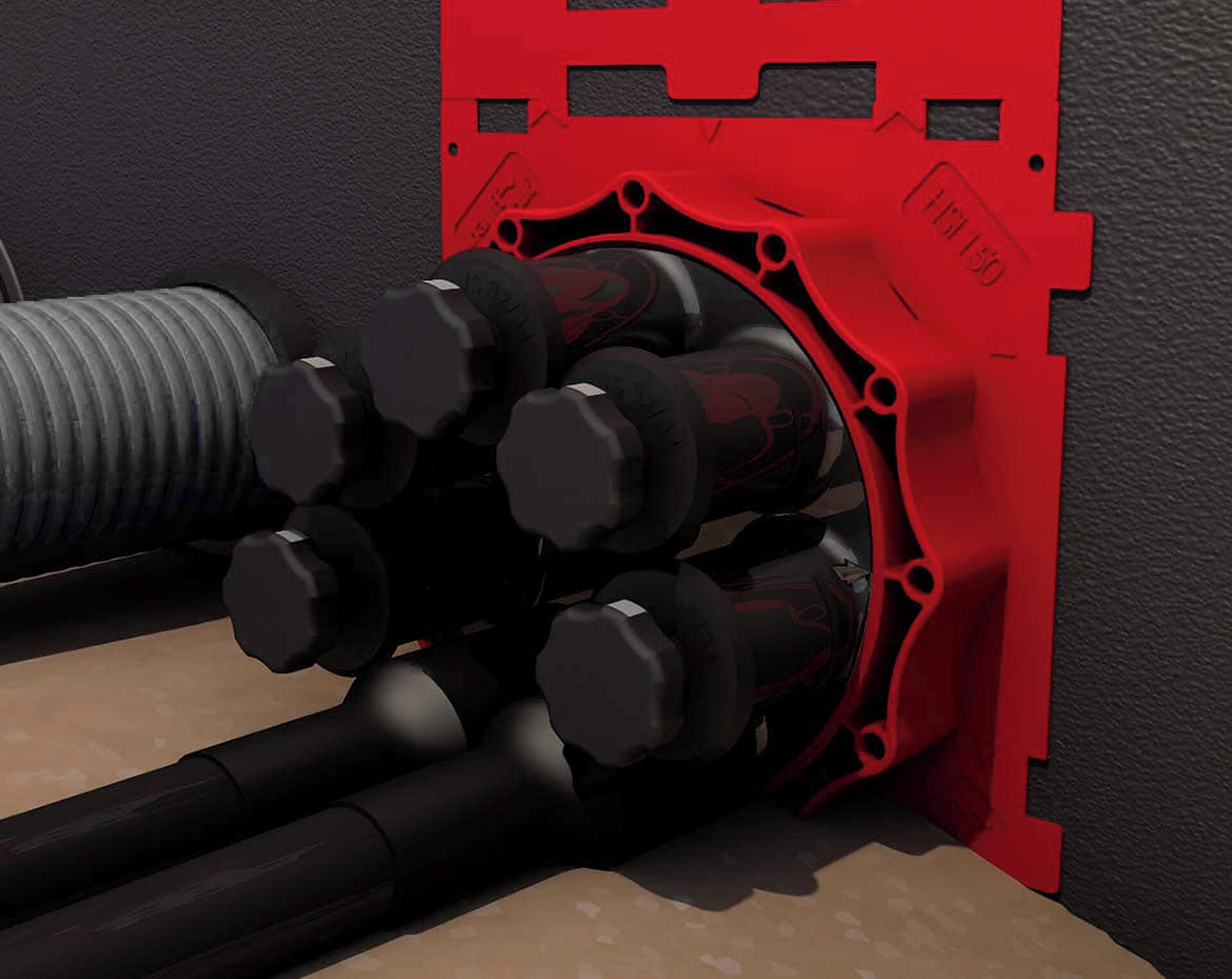

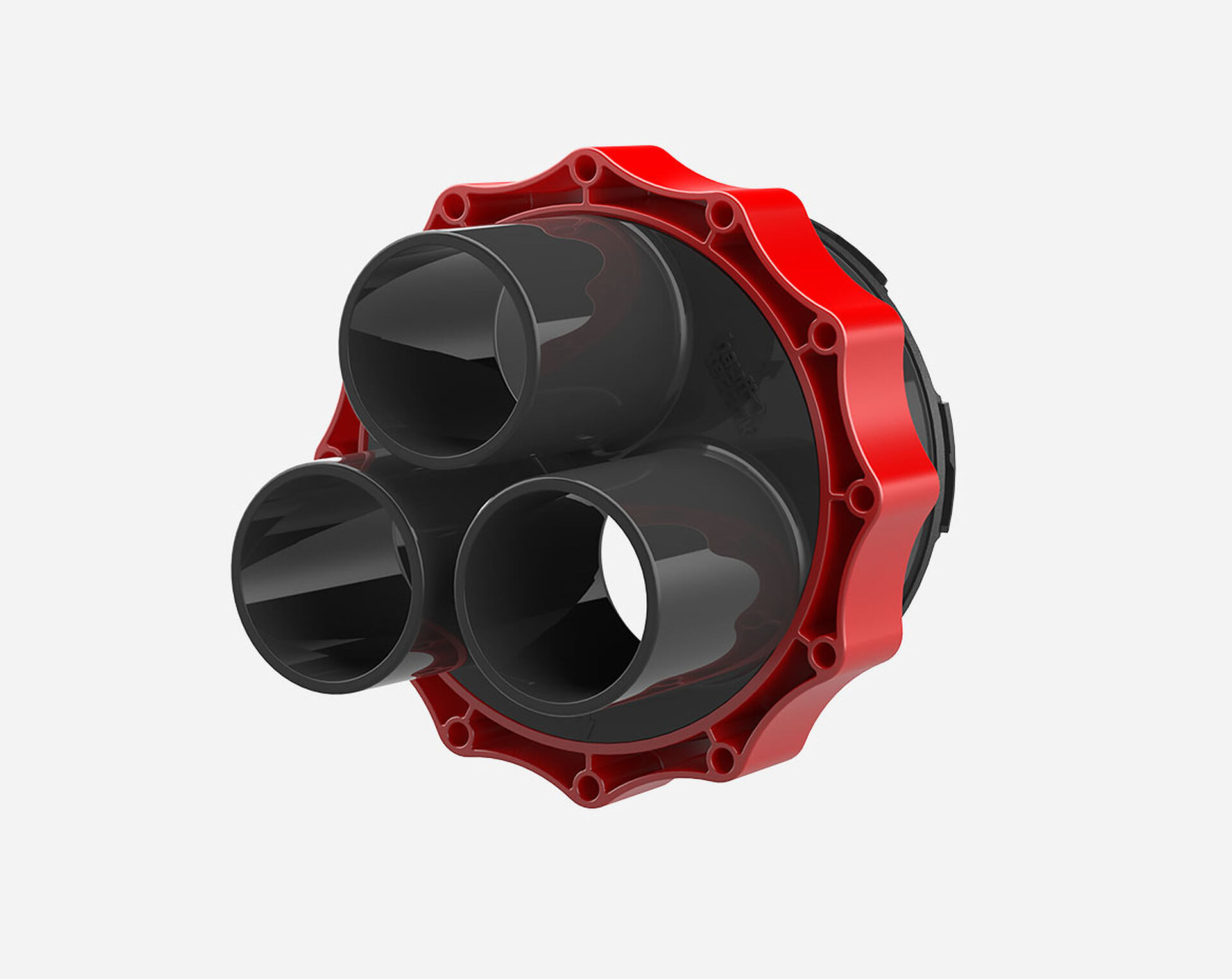

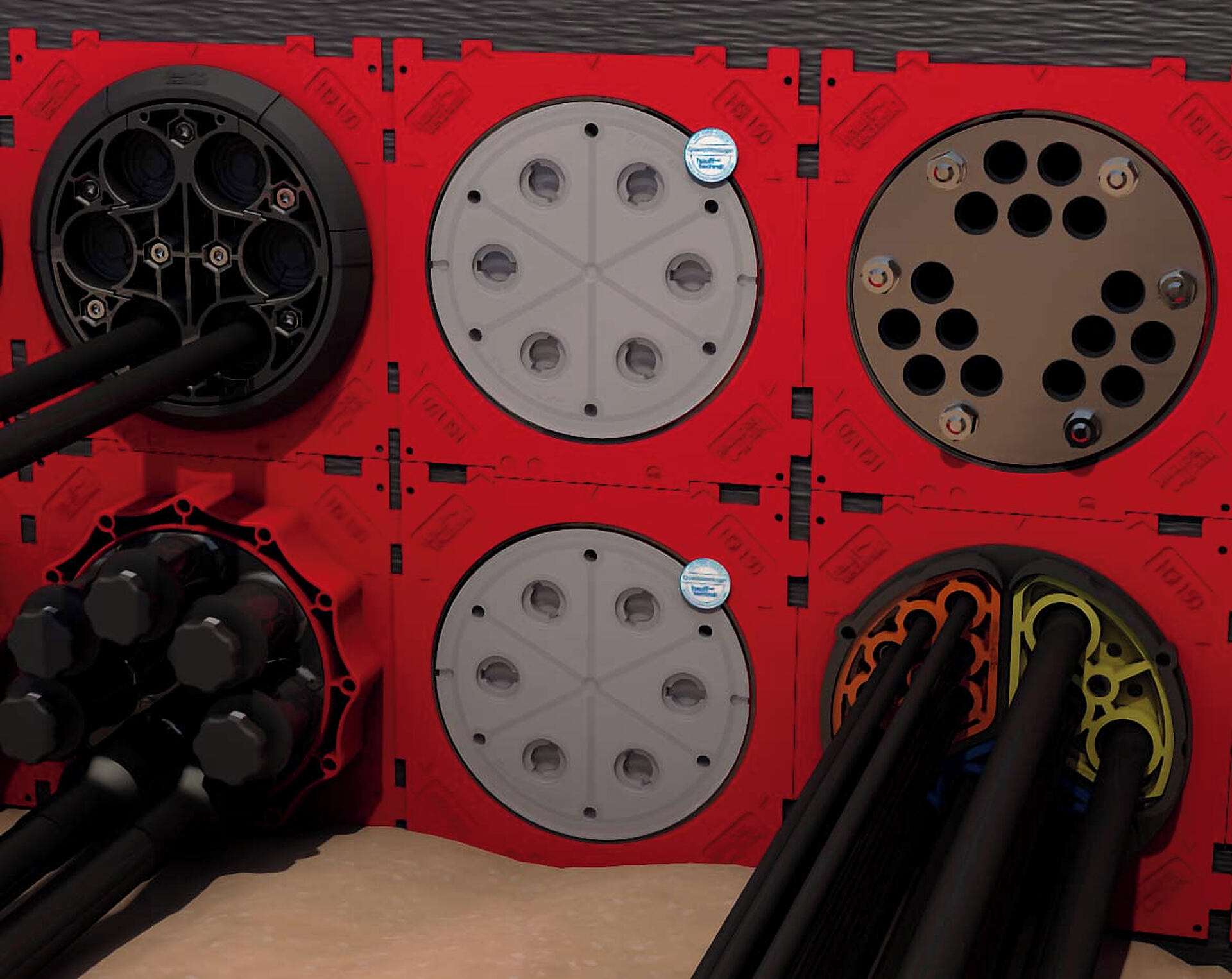

Choosing the correct cable entry for each situation is vital for a complete sealing of the building entry. Hauff-Technik’s HSI90 and HSI150 cable entry systems offer various cable entry options, with a focus on future security, installation flexibility, and planning confidence.

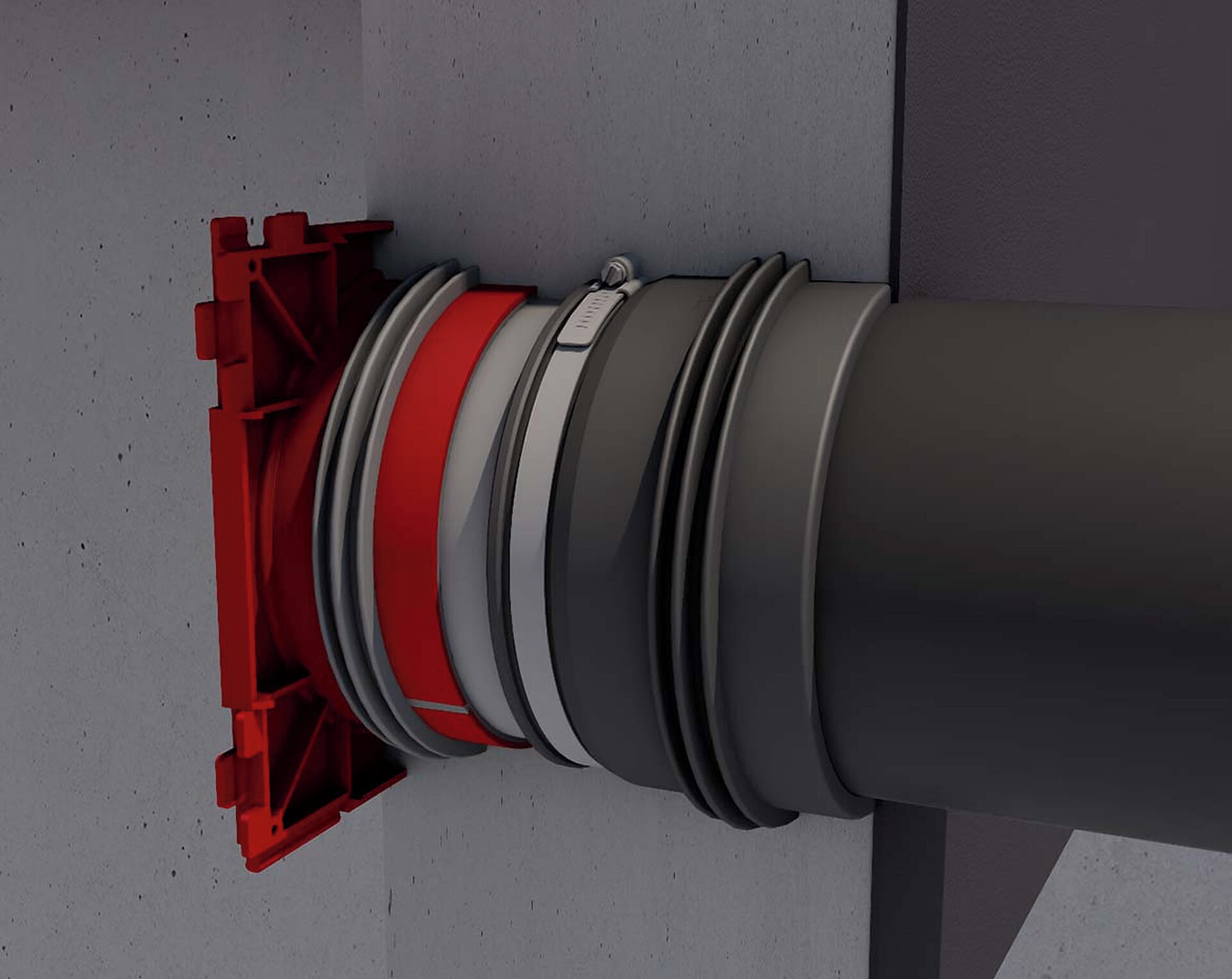

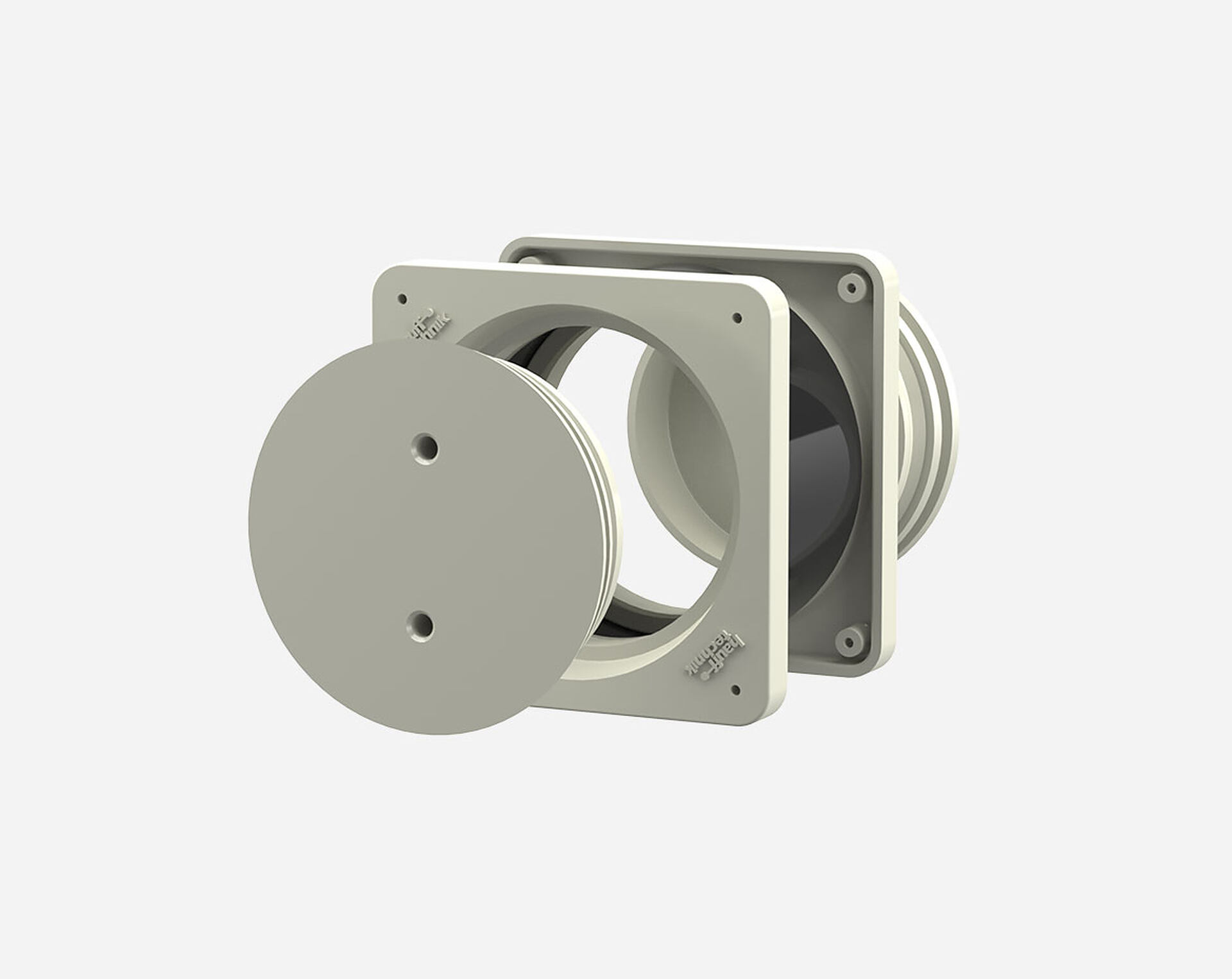

Single wall inserts with rubber plug sleeves are one option, suitable for pipe diameters up to 160 mm. These are ideal for large utility lines, ensuring gas and water tightness, with the added benefit of pressure resistance against concrete.

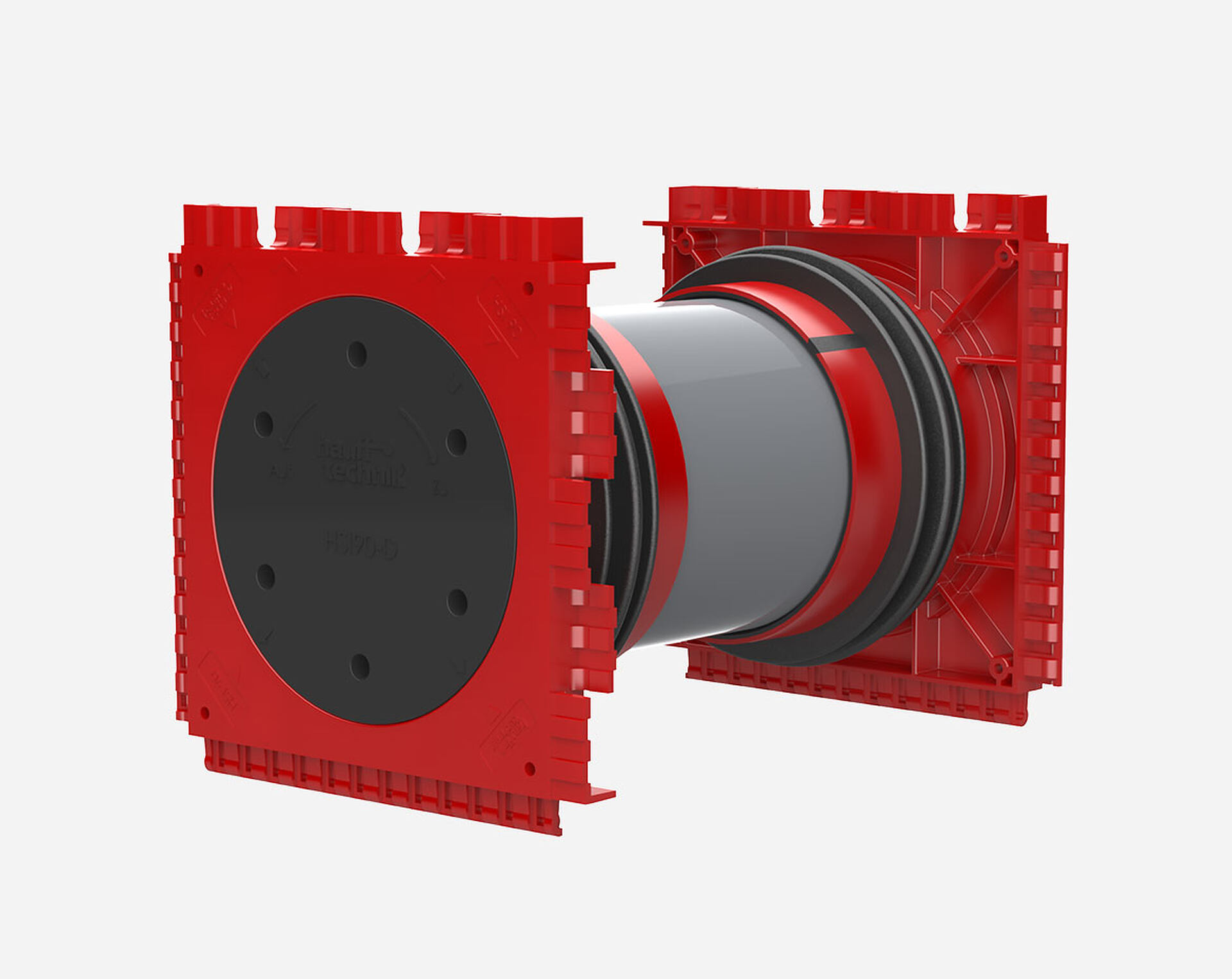

For smaller conduits, wall inserts and system covers Hauff-Technik provides a multi-entry solution via a single interface. These covers are both gas- and watertight and accommodate multiple smaller entries with varying diameters. A combination of different sizes can be housed within one system cover. Even 90 mm entries can hold up to six cables. The sealing of individual lines can be achieved using cold or heat shrink techniques.

Additionally, these systems allow for individual seals or entire entries to be temporarily unused. With universal closing cover, these unused entries can be sealed pressure-tight. Later, these free interfaces are ready for new utility lines, without the need for time-consuming drilling or additional work for sealing.

Cable Seals for Core Drilling

When retrofitting utility lines, core drilling or an existing conduit pipe is often the go-to method. Proper sealing of the core drilling is essential for ensuring optimal cable sealing. Hauff-Technik offers a wide range of press seals tailored for this purpose.

The rubber components in the press seals ensure a tight connection with the building foundation, making the system gas- and watertight, regardless of the installation angle. Hauff-Technik provides press seals for core drillings and conduit pipes with diameters of 80, 100, 150, and 200 mm.

These press seals are equipped with system covers that allow multiple utility lines to pass through a single core drilling. The number of lines depends on the size of the drilling, cable diameter, and the chosen cable entry system. Up to ten cables can be routed through a single core drilling. For unused drillings or empty conduits, blind seals can be used to provide gas- and watertight protection, allowing for future expansion without additional drilling.

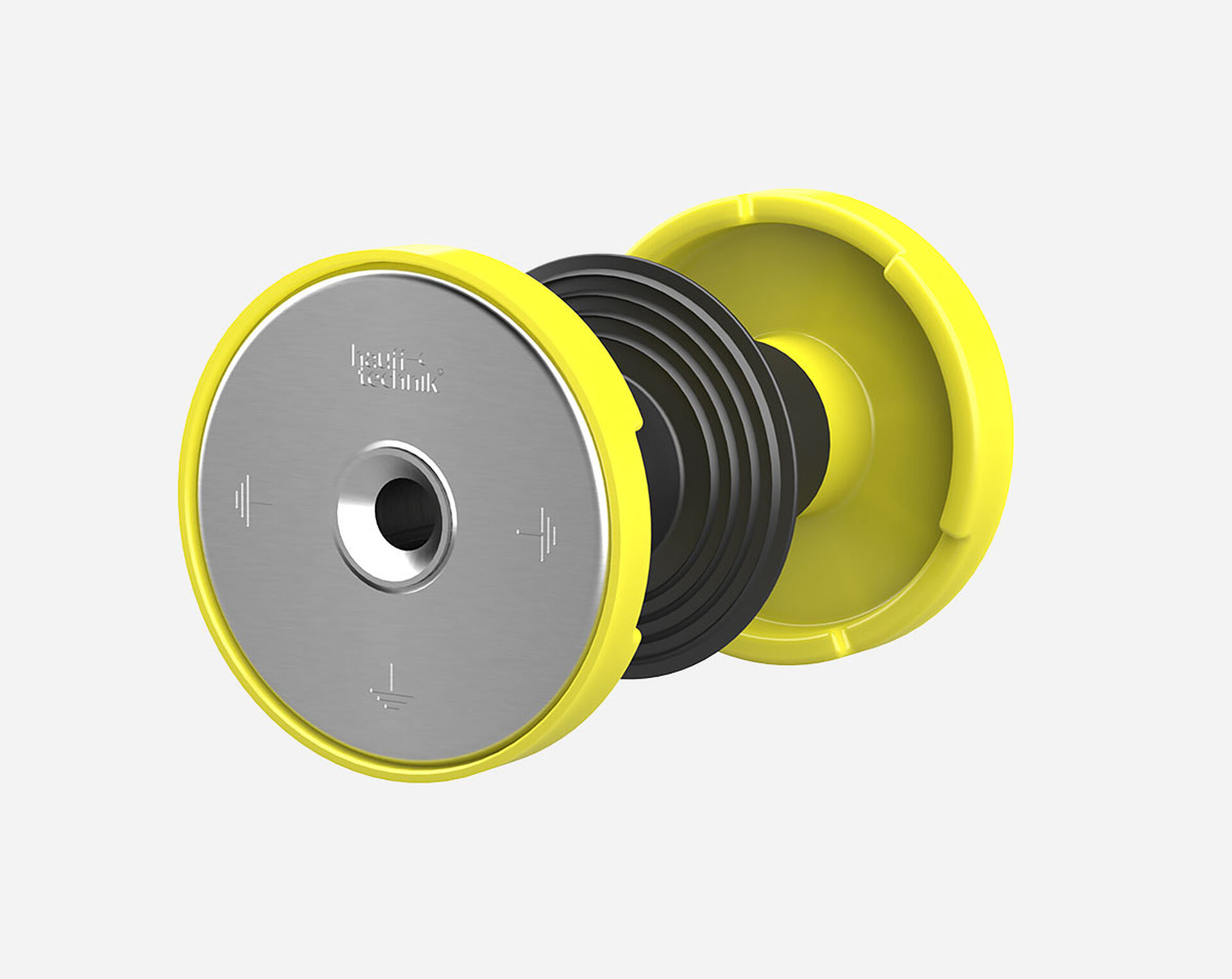

An even easier option is to use sealing cushions with self-inflating technology. These cushions can be quickly installed without tools, fitting directly around the cables. The cushion and cable are inserted into the building through a core drilling or conduit pipe. The self-inflating cushion fills the space between the cable and the core drilling, ensuring a secure seal.

Hauff-Technik’s sealing cushions are available for core drillings with diameters between 19 and 135 mm, and for cables and pipes with diameters ranging from 5 to 99 mm. These solutions are gas- and watertight up to 0.5 bar.

Help us improve our website service.

Where would you place yourself?

Architect & designer

Wholesaler

Telecoms

Utility company

Installer

Construction company

Please choose your region

-

Belgium

Belgium

-

Česko

Česko

-

Danmark

Danmark

-

Deutschland

Deutschland

-

España

España

-

France

France

-

Global

Global

-

Hrvatska

Hrvatska

-

Italia

Italia

-

Luxembourg

Luxembourg

-

Magyarország

Magyarország

-

Nederland

Nederland

-

Österreich

Österreich

-

Polska

Polska

-

Schweiz

Schweiz

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Global

Global

-

USA

USA

-

Global

Global

-

India

India

-

中国

中国

-

Global

Global

-

الإمارات العربية المتحدة

الإمارات العربية المتحدة